- Contact us

- 82-55-322-3995

- 82-55-323-3995

- Emailcsnt@csnano.com

Metal Paste

Home > Product > Metal Paste

Silver Paste

Product property

- Nano silver particle offers excellent fine patterning with superior process capability- Wide range of curing temperature for plastic films (PET, PI, PVC, PE) & glass

- Conductivity is as low as bulk silver offering high conductivity even in micron scale patterned electrode

- For conventional & cutting-edge printing technologies

- Touch screen products

- OLED, EMI shielding, RFID, Flexible Display,

- FPCB(Flexible Printed Circuits Board)

Product Specification

AGP 200 series |

AGP 200H series |

|

|---|---|---|

Silver content(%) |

60 - 80(<400nm,1μm) |

60 - 70(<400nm,1μm) |

Viscosity(cps) |

10,000 - 30,000 |

20,000 - 50,000 |

Printing method |

Screen, Gravure, Off-Set |

Screen, Gravure, Off-Set |

Curing condition |

- 120 - 180℃ / 30min |

- Preheating : 120 - 150℃ / 10min - Firing temperature : 500 - 700℃ /10min |

Specific resistivity(Ωcm) |

< 10-5 (PET)(5μm) |

< 10-6(Glass)(5μm) |

Substrates |

Plastic film, Glass |

Glass, Ceramic |

Application

- RFID (Radio Frequency Identification)- FPCB (Flexible Printed Circuit Board)

- EMI (Electromagnetic Interference)

- Solar Cell

- Other Flexible Display and Printed Electronics

Copper Paste

Product property

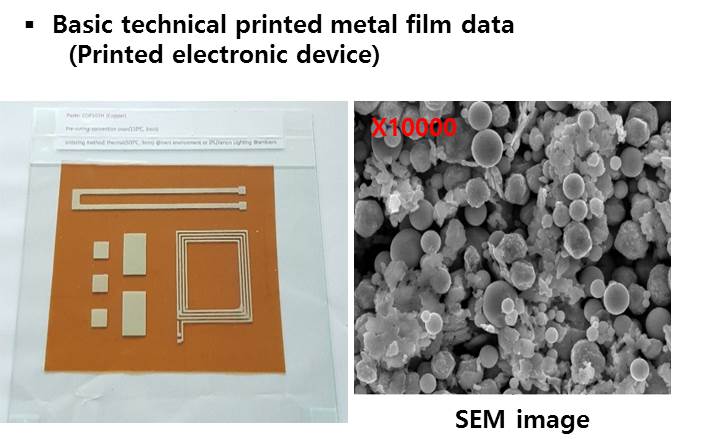

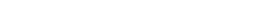

High temperature paste- Screen printing process allows metal pattern formation

- A thermal sintering technique or a light sintering technique of a drying condition of 110℃ and a nitrogen atmosphere of 500℃ was applied

- Resistivity value 2 × 10 -5 Ω · ㎝ can be implemented

Low temperature paste

- Screen printing process allows metal pattern formation

- A thermal sintering technique or a light sintering technique of a drying condition of 110℃ and a nitrogen atmosphere of 250℃ was applied

- Resistivity value 2 × 10 -5 Ω · ㎝ can be implemented

- Easy application of metal plating technology

Product Specification

COP 100 series |

COP 100H series |

|

|---|---|---|

Copper content(%) |

60 - 70(< 1μm) |

60 - 70(< 1μm) |

Viscosity(cps) |

15,000 - 45,000 |

20,000 - 50,000 |

Printing method |

Screen, Gravure, Off-Set |

Screen, Gravure, Off-Set |

Curing condition |

- Preheating :110℃ / 5min - Sintering : : 250℃ / 20min |

- Preheating :120℃ / 5min - Sintering : 500 - 600℃ / (1-5min) ( Vacuum or Inert gas charge ) |

Specific resistivity(Ωcm) |

1x10-4 - 1x 10-5(Glass)(5μm) |

< 10-5 (Glass)(5μm) |

Substrates |

Polyimide film, Glass |

Glass, Ceramic |

Application

- RFID (Radio Frequency Identification)- FPCB (Flexible Printed Circuit Board)

- EMI (Electromagnetic Interference)

- Solar Cell

- Other Flexible Display and Printed Electronics